Exploring the Mechanics of Flywheel Energy Storage Systems

Written on

Chapter 1: Introduction to Energy Storage

The recent endorsement of the Green Deal by the European Commission is set to accelerate the transition towards renewable energy systems. However, the inherent variability and unpredictability of renewable energy sources necessitate significant advancements in energy storage solutions to ensure reliable electrical system operations.

The electrical grid comprises a complex network of generators, transmission lines, and consumers, operating at specific frequencies (50/60 Hz) and standard voltage levels. To maintain stability, the energy produced by generators must align with the demand from consumers, thereby ensuring a balance between production and consumption. Energy storage systems play a crucial role in compensating for any discrepancies.

Section 1.1: Understanding Flywheel Technology

What exactly is a flywheel? Essentially, it is a large wheel connected to a rotating shaft designed to stabilize power delivery from a motor to machinery. The flywheel's inertia helps moderate fluctuations in engine speed, while also storing excess energy for future use.

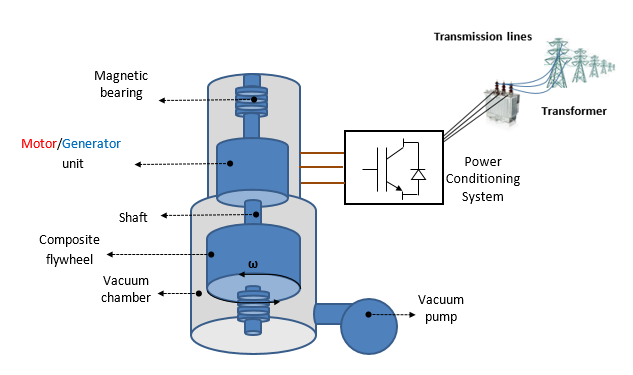

One of the most promising advancements in energy storage and regulation is the Flywheel Energy Storage (FES) system. But how does it function? A rotor with substantial mechanical inertia is housed in a robust cylindrical container, which is maintained at a certain vacuum level to minimize noise and aerodynamic drag. This is further enhanced by magnetic bearings or superconducting materials. The flywheel utilizes electrical energy to either accelerate or decelerate, with the kinetic energy being exchanged with the electrical grid through an integrated motor/generator along the rotation axis. The energy storage capacity is influenced by the rotor's speed and inertia, which is determined by its design, mass, and radius.

Section 1.2: Characteristics and Applications

Flywheels can achieve rotation speeds up to 100,000 RPM, with specific energy ranging from approximately 5 Wh/kg to 100 Wh/kg, and efficiency levels reaching up to 95%. Unlike synchronous compensators (or rotary capacitors) that help regulate voltage without storing energy, flywheels can rapidly respond to short-term power fluctuations caused by sudden changes in wind or solar energy generation.

Below is a schematic representation of a Flywheel Energy Storage system.

Advantages of Flywheel Energy Storage:

- Power and energy are largely independent

- Fast response to power demands

- High specific energy potential

- Long cycle and calendar life

- Quick recharge times

Disadvantages of Flywheel Energy Storage:

- Challenges in maintaining durable, low-loss bearings

- Mechanical fatigue and stress limitations

- Material constraints around 700 m/sec tip speed

- Potentially hazardous failure modes

- Limited discharge durations

Chapter 2: Future Prospects

Recently, pilot projects utilizing flywheel technology have been developed. The first significant facility, capable of delivering 20 MW and 5 MWh for 15 minutes, was established for grid frequency regulation and began operations in Stephentown, New York, in 2011. This model was replicated in Hazle, Pennsylvania.

The future expansion of this technology relies on reducing current high costs and leveraging its versatility across various applications, such as uninterruptible power supplies (UPS) for short outages or in sectors like transportation and space exploration for ultra-fast recharging.

What innovations lie ahead in the energy sector? Is marine energy a viable future source? Explore the potential and various types of energy solutions in upcoming discussions.

You can connect with me on Twitter and LinkedIn for more insights on various topics. For additional information about my work, feel free to visit my website. Thank you for reading, and see you soon!